Kodak, once synonymous with cameras, has reinvented itself as a prominent player in the Indian TV industry, thanks to the relentless efforts of Mr. Avneet Singh Marwah and his team. It is their hard work, even having a thwack of Covid period, they are still operating with greater production to meet the increased demand. Their commitment to providing good budget Smart TVs with quality has propelled Kodak TVs to the forefront of the market, challenging perceptions and setting new standards. Recently, we visited the Kodak TV assembling unit to experience their automated production line and also had a chit-chat with Mr. Avneet, Director and CEO of Super Plastronics Pvt. Ltd.

Exploring the Kodak Facility:

A visit to the Noida-based Super Plastronics provides a fascinating insight into the manufacturing process behind Kodak TVs. Guided by Mr. Avneet Singh Marwah himself, we had immersed in an organized facility where every stage of production is carried out with precision and care.

Streamlined Production Process:

The manufacturing process begins with the consolidation of all TV components, including the PCB board, panel, and remote, in one location. Each component is selected by hand meticulously and undergoes rigorous testing to ensure quality and reliability before being integrated into the final product. This initial stage sets the foundation for a seamless production operations.

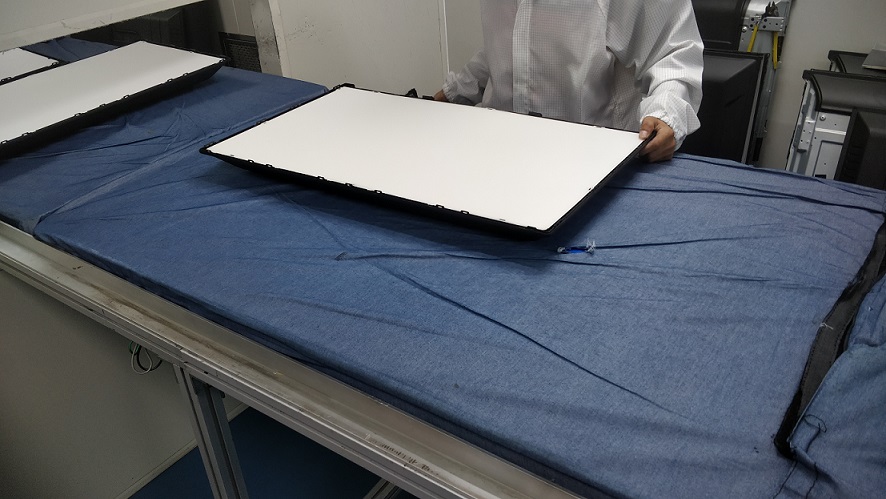

Outer frame selection process and other items to start shaping a framework for Smart TVs…

PCB integration, here selected ones by engineer set forward for further assembling process.

Precision Assembly:

One of the key stages of assembly is the shaping of the front panel of Kodak TVs. In a dedicated area equipped with specialized equipment, LED displays, and panels are meticulously sealed to the plastic molded body of the TV. Strict protocols, including the use of anti-static clothing and masks, are followed to maintain a clean and dust-free environment, ensuring optimal performance and longevity of the TVs.

Testing Procedures:

Before a Kodak TV leaves the manufacturing facility, it undergoes a series of comprehensive tests to verify its performance and functionality. Skilled technicians carefully inspect every component, from the display panel to the internal circuitry, to ensure that they meet Kodak’s quality standards. Specialized testing equipment is employed to assess factors such as image clarity, sound quality, and connectivity options, ensuring that each TV delivers an immersive viewing experience.

Quality Assurance Measures:

Even after going through multiple testing processes, a quality check inspector will pick randomly any Smart TV from the final lot to test and ensure the unit meets the specified criteria, if it failed the whole lot will go through further inspection or rework, ensuring that only flawless products reach in the hands of consumers.

Packaging Protocols:

Once a Kodak TV has passed all quality checks, it undergoes heedful packaging to safeguard it during transit and delivery. Specialized packaging materials such as EPS Thermocol are used to protect the delicate components of the TV from damage, ensuring that it arrives in good condition. Each TV is securely encased in foam padding and placed in a sturdy cardboard box, complete with protective inserts to prevent movement and minimize the risk of impact during transportation.

Final Inspection:

Before being dispatched for delivery, every packaged Kodak TV undergoes a final inspection to verify that it meets the company’s standards. Trained inspectors perform the Vibration test in addition to others ensuring that transporting the final packed unit through the rough terrain of rural areas will not cause unexpected internal or external damages. Only after passing this final inspection, the TV is deemed ready for shipment.

Our journey of experiencing the Kodak TV’s assembling facility was not just end here, we also had some spare time with Mr. Marwah to learn his further plans for the SPPL and understand how the company has jostled with other players in the Budget Smart TV segment of India to make its space. Here is a glimpse of the questions we asked in our one-to-one interaction with him.

A: Our journey in the TV industry has been a remarkable one, marked by continuous improvement and learning. From the launch of our first basic LED TV to the diverse range of Smart TV products we offer today, we’ve undergone significant growth and evolution. Throughout this journey, we’ve encountered challenges and made mistakes, but each experience has taught us valuable lessons. No technology partner will ever, you know, agree to give their technology to you without any quantum.

You have to reach that point of time with you should have that kind of equity in

the market either from the brand or from the manufacturing perspective or you know, you must have a very good story with any other category so that that technology partner has

that kind of confidence. Otherwise, if you are new, nobody will bet on the technology and nobody will give you the trans-shift of the technology. So, we’ve learned the importance of strategic decision-making, resource allocation, and adapting to changing market dynamics.

Q: Kodak also had a product category of Speakers, what happened to that?

A: While our primary focus has been on TVs, we ventured into the speaker market at one point. However, we realized that we may have missed out on a significant opportunity due to our intense focus on TVs. The speaker market in India was still in its nascent stages, and we may have underestimated its potential. This experience taught us the importance of market research and strategic diversification.

Q: Is Kodak planning to revisit the speaker category in the future?

A: Yes, we are exploring opportunities to re-enter the speaker market. We’ve observed the developments in the industry over the past few years, including disruptions caused by new brands and funding initiatives. We’re strategizing to compete effectively in this space while ensuring we deliver the right products to meet consumer demands at the right time.

Q: Kodak has introduced various technologies in its TVs. Are there any plans to venture into OLED technology?

A: OLED technology is certainly on our radar. However, securing partnerships for OLED technology can be challenging due to its market dynamics. While OLED offers significant advantages, including superior picture quality, there are complexities involved in obtaining the technology. We’re in discussions with potential partners and remain open to incorporating OLED into our product lineup. Also, the OLED tech bearers have rightly

figured out that they had a market share of about 25-26% which is now around 6%-7% and if they allow OLED in the affordable category, I think they will lose that market share. So they have a huge fear.

You will be surprised to know last year OLED celebrated 10 years and still, it’s not a mature technology in India. So one of the key reasons has been this only. Well, still we are open, we have already talking to them for the last couple of years. Let’s see if this year they agree to open OLEDs.

Q: How does Kodak prioritize customer support and after-sales service?

A: Customer support and after-sales service are paramount for us. We understand the importance of providing exceptional service to our customers, particularly in the competitive TV market. We’ve established a robust infrastructure to offer door-to-door service across thousands of pin codes in India.

I think it’s very difficult to satisfy customers with their perception, everybody has their

own sense of understanding the things, and it becomes a little difficult at times. But still, by having, you know, we have learned so many things from last so many years, we’re improving day on day wise. There have been a lot of challenges, I would not say it’s a smooth ride, there have been a lot of obstacles when it comes to service. Whatever we learn, we try to put that learning into the field and always try quickly close the calls as soon as possible.

Despite the challenges, we’re committed to continually improving our service standards to meet customer expectations.

Q: How does Kodak ensure quality and productivity in its manufacturing processes?

A: We continuously invest in upgrading our manufacturing facilities to enhance efficiency and minimize manual intervention. Our focus is on leveraging technology and innovation to improve product quality and reduce failure rates. We prioritize user-friendly design and aim to minimize the need for repairs or replacements through rigorous testing and R&D efforts. We have integrated the AI in our production line to minimize the failure rate.

To maintain quality we also focus on upgrading our production line and the next time when you visit our factory again, you will see a lot of upgrades happening. Well, our number one priority is to create an user-friendly environment, and the second is to minimize the failure rate. I always believe that the TV should not open. It’s there for sale and use for years and years, it should not open and must be completely risk-free. So, unless we achieve one of the best return rates in the country, I think till then we will keep on trying, however. a zero percent failure rate is not possible in electronics.

Q: What are Kodak’s plans for expanding its production capacity and product offerings?

A: We’re committed to scaling up our production capacity to meet growing demand. We are investing 500cr in Hapur to build a manufacturing unit that will specifically focus on TV manufacturing, which will scale up us from making 700,000 to 2 million Units per year. Our investment in manufacturing infrastructure, coupled with strategic partnerships, will enable us to introduce new products and expand our range of offerings. We’re particularly focused on offering larger screen sizes at affordable prices to cater to evolving consumer preferences.

Q: SPPL has multiple TV brands under its umbrella. What is the strategy behind this approach?

A: Our multi-brand strategy allows us to cater to diverse consumer segments and distribution channels. Each brand serves a specific market niche, whether it’s online platforms, offline retailers, or premium segments. By offering a range of brands, we can address varying consumer needs and preferences while maximizing our market reach. For example, Thomson is exclusive to Flipkart, and Blaupunkt is available only online. Kodak is a brand that is available across all categories i.e. offline, online platforms, and general trade.

A: Blaupunkt has been well-received by consumers, particularly those seeking premium features and sound quality. I think this is one of the few brands, where we sell more 55-inch TVs than 32. We’ve observed strong demand for Blaupunkt TVs, especially in larger screen sizes. The brand’s legacy in sound technology has resonated with customers, leading to positive feedback and sales performance. That’s the reason why with Blaupunkt QLEDs or 4Ks, customers are not buying soundbars because we are giving the appropriate sound of 60 watts, 50 watts, etc. in the television.

A: No, I think Kodak is also for premium users because Kodak is the only brand in the country among very few brands in the world which has that kind of nostalgia. Kodak offers QLEDs and all the larger 4K sizes, so it is widely accepted and used as an affordable Smart TV by even premium users. However, Blaupunkt is ultra-premium and it targets those consumers where the pocket size is much larger.

Q: What can consumers expect from Kodak in terms of new product launches?

A: We have exciting new launches planned, focusing on larger screen sizes and affordability. Our goal is to offer high-quality TVs with advanced features at competitive prices. We’re constantly innovating to stay ahead of market trends and deliver products that meet the evolving needs of our customers.

We’re focusing on big sizes. I think 32, we’re not focused at all. It’s a size that we wanted to initially exit. But for selected users, we will have 32, because I think India is going towards upper big sizes. And our target is how to give big sizes at a very, very affordable pricing.

I think that’s the next big target where, you know, I’ve seen top three players are giving large screen television worth 10 lakhs, 20 lakhs, 30 lakhs; we want to be under 3 lakhs, sort of, you know, that same TV.

Q: How does Kodak maintain affordability while ensuring product quality?

A: Our approach involves complete backward integration and in-house manufacturing, which allows us to maintain control over costs and quality. Unlike some of our competitors which are not anymore in the market such as OnePlus who rely on heavy discounts and cash-burn strategies, we prioritize sustainable growth and profitability. By leveraging our manufacturing capabilities and operational efficiencies, we’re able to offer affordable TVs without compromising on quality.

Q: What are your expectations from the upcoming budget and government policies?

A: I think the government is not realizing that markets are becoming tough. We hope to see supportive policies from the government, particularly in areas such as GST reduction for TVs above 32 inches and incentives for local semiconductor manufacturing. These measures would boost the electronics industry and encourage investment in domestic manufacturing. Additionally, investments in education and skill development are crucial for long-term economic growth and sustainability.

Q: What advice would you offer to startups looking to enter the IT or manufacturing sector?

A: Startups should prioritize sustainable growth and profitability over short-term gains. Rather than relying solely on burning cash for customer acquisition, they should focus on achieving positive EBITDA and building a strong foundation for future growth. Additionally, investing in infrastructure and skill development is essential for success in the manufacturing sector.

Q: Are there any upcoming offers or sales events for Kodak TVs?

A: We have several sales events planned throughout the year, including Republic Day, Holi, and year-end sales. These events will offer customers attractive deals and discounts on our products. We’re committed to providing value to our customers and ensuring they have access to high-quality TVs at competitive prices.

Related Posts

What is a juice-jacking attack? How can we be safe from such attacks?

Getting the right dashcam for your needs. All that you need to know

WhatsApp iPad App Gets Major Overhaul, Adds New Communities Feature

Moto G85 5G launched in India but is unlikely to beat VIVO or XIAOMI

Rise of deepfake technology. How is it impacting society?

Smartphone Apps Get Smarter- Meta AI’s Integration Across Popular Platforms